Potable water network

A) Potable water pipe location and Detecting

- It is often that water network operators do not have a reliable register of the state of the network (after road construction, some of the valves were buried under pavements or under roads, or maybe even no available maps …etc) .

- Our team provides the latest equipment and high experience that enables us to create asbuilt and very accurate information to facilitate decision-making.

- Our pioneer equipment detects and locates , valves, manhole covers, and even metallic and non-metallic pipes

- In addition to determining the depth and creating GIS maps for those located utilities so you would never miss them again.

potable water pipe location and Detecting

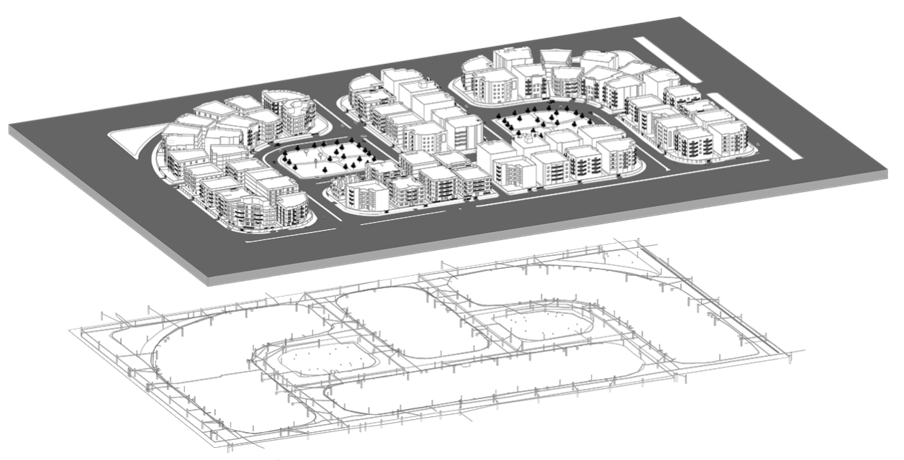

B) 3D modeling

We provide visualization of potable water networks and connect them to the above-ground facilities portfolio of projects to increase their productivity via higher quality results in a reduced time frame using the latest technology in these fields from reliable market-leading brands.

Our team provides the latest equipment and high experience that enables us to create asbuilt and very accurate information to facilitate decision-making.

3D visualisation with potable water network

2) Hydraulic Analysis

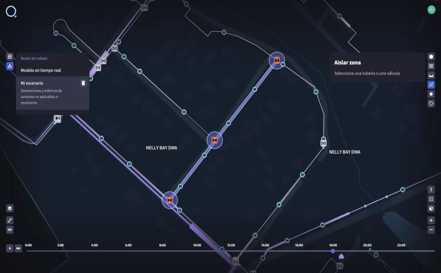

A) Hydraulic Model

hydraulic analysis of the potable water network to Optimize network performance and understand the flow dynamics, pressure variations, and overall performance. Hydraulic modeling software will simulate water movement, to better understand and identify bottlenecks, areas of high pressure, and potential weak points, leading to a much more informed decision-making procedure.

Our team provides the latest software for hydraulic analysis

Hydraulic model

B) Hydraulic Model Calibration

Calibrate the hydraulic model using real-world data to ensure its accuracy and reliability. Comparing modeled data with actual performance data from flowmeters and pressure data loggers will refine the model’s predictions and enhance its ability to simulate network behavior.

Our team provides the latest software for hydraulic analysis

Hydraulic Model Calibration

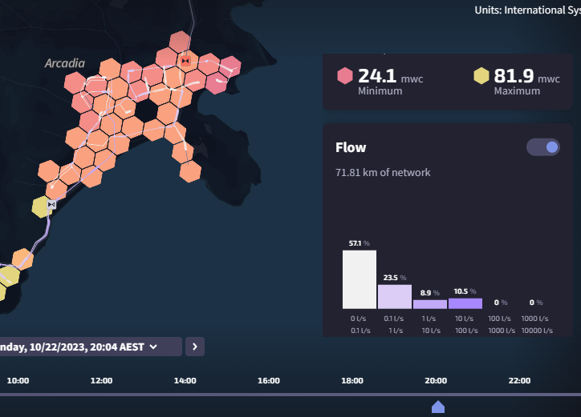

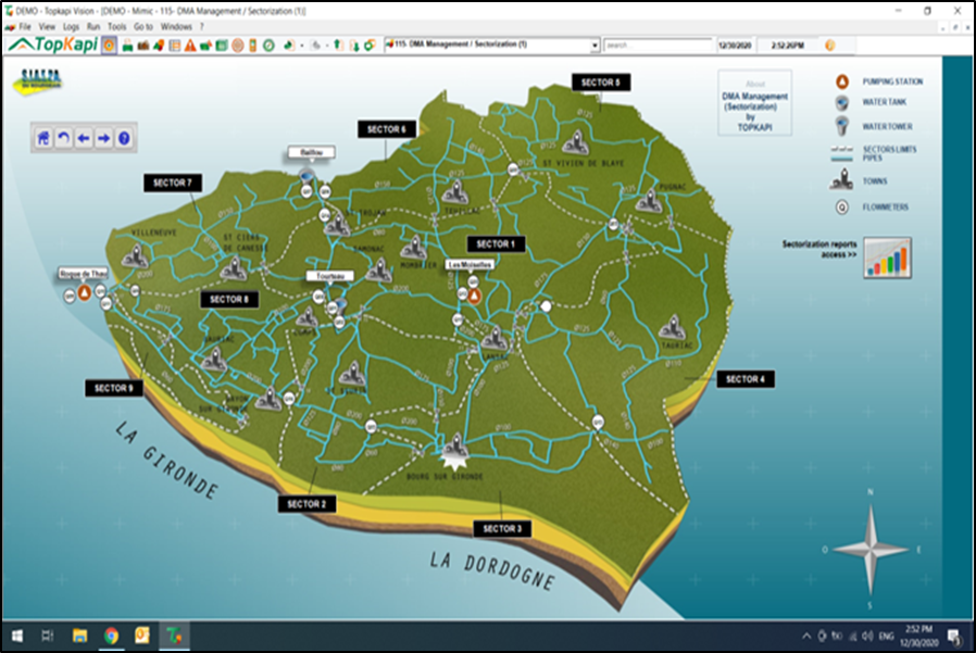

3) DMA (District Metered Areas)

A) DMA design

Design and define District Metered Areas (DMAs) to segment the water distribution network into manageable zones. DMAs enable precise monitoring and analysis of water flow and pressure to minimize non-revenue water (NRW) one of the most challenging problems for water utility owners and operators to overcome.

We can study and analyze the potable water network to design a DMA to determine the accurate location and zone boundary to place flow and pressure measuring devices and placement of the type of flowmeter suitable for measuring

Hydraulic Model Calibration

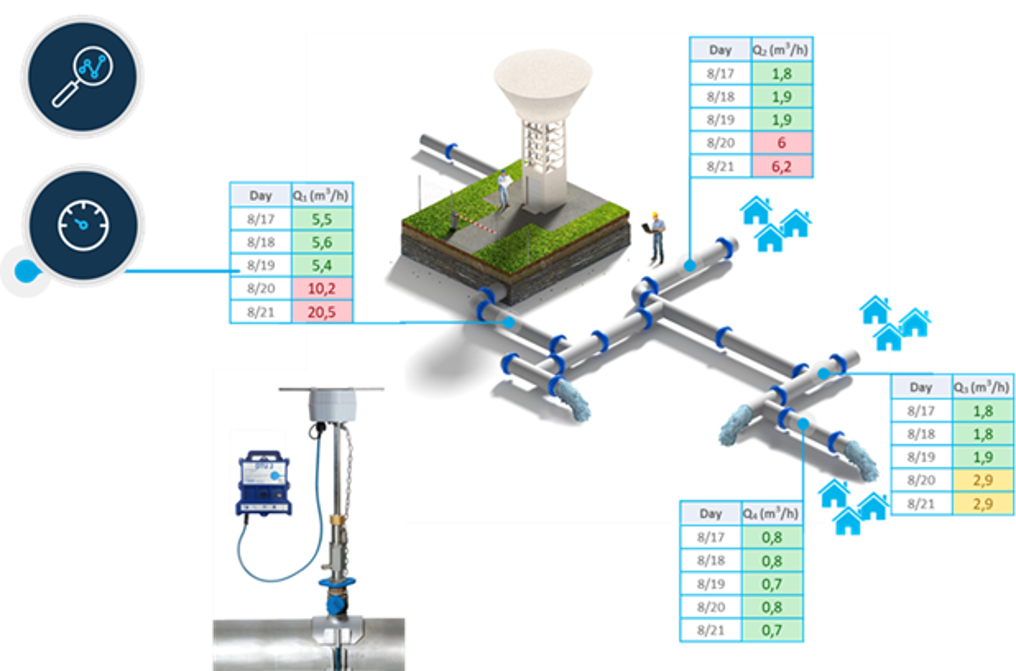

B) DMA Deployment

Based on the DMA design for potable water networks, the specific measuring points created, and measuring flow and pressure instruments we can install a permanent flowmeter and pressure logger to collect data and data analysis strategy with the information being provided from the fixed flowmeters installed on the network

We have the latest solutions, instruments, and experts that enable us to install and measure under difficult hydraulic conditions using the latest technologies.

C ) Data management and analysis

Develop a robust data management system capable of aggregating, processing, and analyzing large volumes of sensor data after DMA deployment .

Utilize advanced data analytics and machine learning algorithms to detect anomalies, predict leaks, and optimize water flow.

D) pressure management

The Pressure management challenges facing water utilities within discussions

centered around sustainability, water scarcity, and the conservation of precious

resources, one topic regularly covered is how utilities can better solve the challenge

of water loss within their network. The need to protect precious resources and

reduce water loss to more acceptable levels has made non-revenue water (NRW) one

of the most challenging problems for water utility owners and operators to

overcome.

•Optimize pressure management system to reduce existing leakage flows. Reducing

pressure in networks by 25% means mechanical stress is avoided and burst

frequencies are reduced by up to 75%.

•Reduce operational, maintenance, and repair costs with restraint fittings.

•Pipe network renewal Extend pipe network lifetime with reliable non-corrosive

connections.

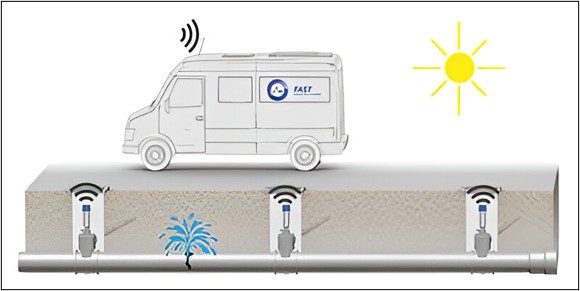

4) Leak Detection

Identification and implementation of leak detection systems. These may include acoustic sensors, pressure sensors, or other advanced technologies to monitor and detect leaks within the DMAs accurately.

Correlators

Ground microphone

Pipe mic

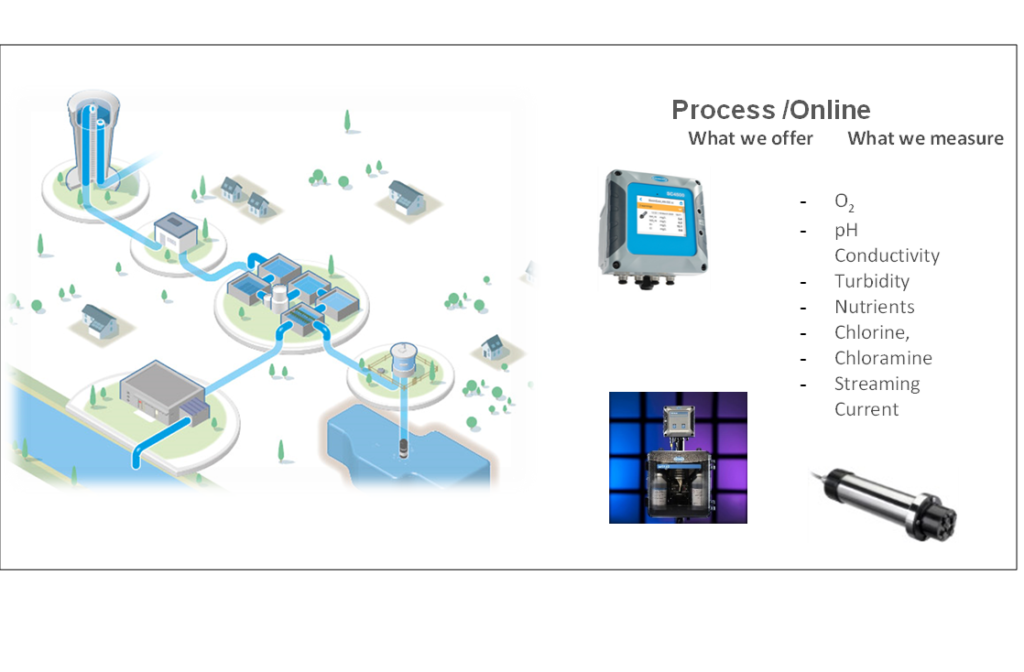

4) Water quality online verification

Continuous process management solutions allow you to manage your processes in real-time, keeping your facility compliant while ensuring water quality 24/7. Managing your process has never been so straightforward.

Breakthrough innovation to simplify your water analysis In-depth resources from our drinking water experts

.